View all product categories

Product Categories

Product Details

Pharmaceutical Automatic Vacuum Cosmetic Emulsifying Machine for Cheese,Cream

Focus on professional manufacturer and supplier for pharmaceutical machinery, pharmaceutical packing material company, who is standing firmly with a good reputation in the industry of China pharmaceutical machinery.

Category:

Product Details

Technical parameter

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Machine Images

The whole equipment of this system is composed of emulsification mixing tank, boiler, pre-treatment boiler, vacuum system, hydraulic system, electric control system, material discharging system and working platform.

Features:

vacuum emulsifying blender is specially designed adopting advanced technology of overseas, according to the cosmetic and ointment production technology. The machine is made up of pretreatment boiler, vacuum emulsifying blending boiler, vacuum pump, hydraulic system, pouring-out system, electric control system and worktable.

Characteristic:

The macine has easy operation, steady capability, good homogeneity, high efficiency, reasonable structure, small volume and high automatic level and easily clean.

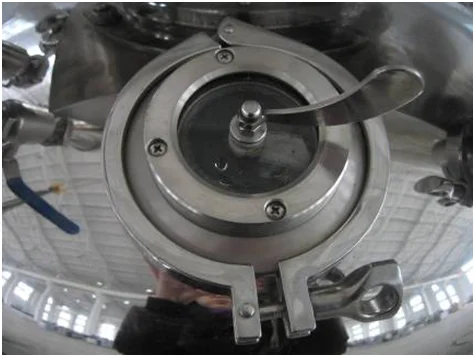

Deatil Pictures

Mixing system for emulsifying tank,

lift up and down freely

Disperser for water phase tank

The row material is sucked into the

emulsifying pot via this pipe, from water and oil pots.

This is the sight window to check the situation of the material.

This is the inlet of additives.

This is the LED lamp.

Vacuum valve and pressure indicator

(for the pressure in the pot)

This is filter, 100mesh generally.

This is bottom valve for discharging the product or connecting the transfer pump

The pipe is water inlet and outlet

Tilting tank

Button control panel

This is the flowing direction of homogenizer.

Sample Images

Inquiry

Related Products

undefined

Dear users, thank you for your attention and support to Pingfang pharmaceutical machinery.

Please leave your suggestions below and provide an effective contact information to receive our feedback. Thank you!

Service Hotline

+86-13825463522© Copyright 2024 Huizhou Pingfang pharmaceutical machinery Co.,Ltd. All rights reserved.