View all product categories

Product Categories

Product Details

DPP-260K High Speed Automatic Plastic AL/AL Medicine Tablet Pill Blister Packing Machine

Focus on professional manufacturer and supplier for pharmaceutical machinery, pharmaceutical packing material company, who is standing firmly with a good reputation in the industry of China pharmaceutical machinery.

Category:

Product Details

Product Description

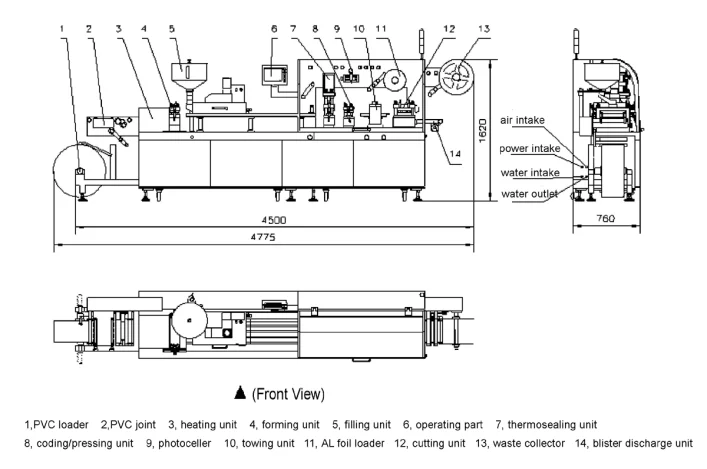

DPP-260K High Speed Automatic Plastic AL/AL Medicine Tablet Pill Blister Packing Machine

Use:

DPP-260K Automatic AL-Plastic (AL/AL) Blister Packing Machine is our advanced equipment designed under updated improvement .It adopts the integral technology applying frequency inverter for speed control and mechanism, electricity, light and air to machine. Its design is in strict compliance with GMP standard and takes lead in the blister packer's field. Featuring advanced functions, easy to operated, high output, the machine is the most ideal packing equipment for large and medium size pharmaceutical enterprises, health food and food stuff trades.

Technical Parameter

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Features

1.Adopts top brand PLC controller with touch screen displayed in Chinese and English, Frequency inverter for speed control, servotraction, which can ensure the length of blister traction adjustable within the range.

2.With thermal temperature control and test, main machine over loading protect, PVC and PTP packing material position test, feeder material position test ,failure automatic debug and alarm, automatic protection and stop running.

3.The machine station module type design of level frame, good sight, safe and convenient operation.

4.Thermal with contact type, positive press formed, air cushion thermal seal upper and lower net, photo register make your product package better.

5.The special design of moulds in rectangle shape, ladder type fixing, provide much convenience and easy to moulds replacement.All material contact parts adopt high quality stainless steel and aluminum metal, slap-up surface treatment craft.

6.The machine has been designed into separated body, which is easily move into lifts or workshops.

2.With thermal temperature control and test, main machine over loading protect, PVC and PTP packing material position test, feeder material position test ,failure automatic debug and alarm, automatic protection and stop running.

3.The machine station module type design of level frame, good sight, safe and convenient operation.

4.Thermal with contact type, positive press formed, air cushion thermal seal upper and lower net, photo register make your product package better.

5.The special design of moulds in rectangle shape, ladder type fixing, provide much convenience and easy to moulds replacement.All material contact parts adopt high quality stainless steel and aluminum metal, slap-up surface treatment craft.

6.The machine has been designed into separated body, which is easily move into lifts or workshops.

Machine Images

Front view

Detailed Images

Inquiry

Related Products

undefined

Dear users, thank you for your attention and support to Pingfang pharmaceutical machinery.

Please leave your suggestions below and provide an effective contact information to receive our feedback. Thank you!

Service Hotline

+86-13825463522© Copyright 2024 Huizhou Pingfang pharmaceutical machinery Co.,Ltd. All rights reserved.