View all product categories

Product Categories

Product Details

GFJX-3A Automatic Aluminum Cream Tube Filling and Sealing Machine

Focus on professional manufacturer and supplier for pharmaceutical machinery, pharmaceutical packing material company, who is standing firmly with a good reputation in the industry of China pharmaceutical machinery.

Category:

Product Details

Technical parameter

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Description

Introduction

This machine has the function of tube storage and feeding besides filling, mark-checking, folding and printing. The aluminum tubes feed and locked into the tube-holder automatically and exactly, it is photo-electricity controlled, no tube, no filling. There are

16 pieces stations totally, run automatically. After tube-mark checking, it begins to fill, four-folding, code printing and exist. There is one calculator to record the production capacity per time, you can clear it to Zero for second production. All of the actions are auto control, which improved the production capacity and saving labor cost.

16 pieces stations totally, run automatically. After tube-mark checking, it begins to fill, four-folding, code printing and exist. There is one calculator to record the production capacity per time, you can clear it to Zero for second production. All of the actions are auto control, which improved the production capacity and saving labor cost.

Feature

The filling speed and accuracy is convenient to adjust, good stability. For different diameter tube, just change the tube-holder, easy and economical.

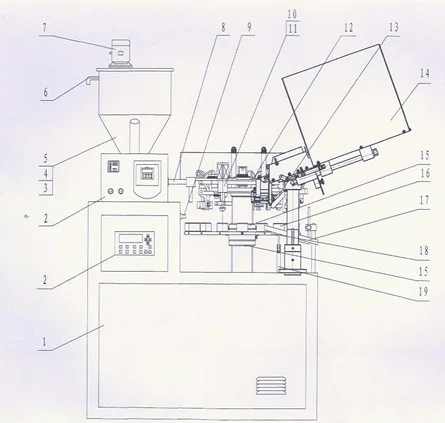

Layout Image

1.Stander 2.Control panel

3.Feed out heating tube 4.Pump heating tube

5.Heating hopper 6.Vent mouth

7.Mixing motor 8.Filling mouth

9.Photo-electricity sensor 10.Alignment mark checking sensor

11.Alignment mark 12.Sealing system

13.Shedder 14.Feed tube system

15.Nut 16.Tube support

17.Discharge hole 18.Indexing disc

19. Mandrill

3.Feed out heating tube 4.Pump heating tube

5.Heating hopper 6.Vent mouth

7.Mixing motor 8.Filling mouth

9.Photo-electricity sensor 10.Alignment mark checking sensor

11.Alignment mark 12.Sealing system

13.Shedder 14.Feed tube system

15.Nut 16.Tube support

17.Discharge hole 18.Indexing disc

19. Mandrill

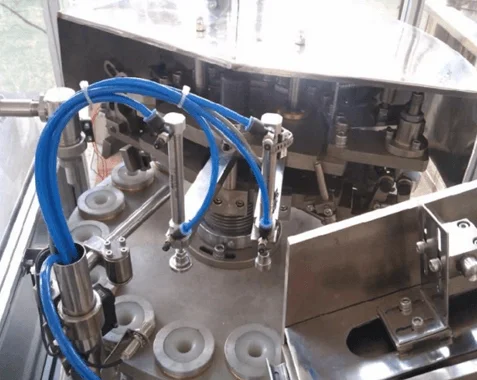

Detailed Images

Inquiry

Related Products

undefined

Dear users, thank you for your attention and support to Pingfang pharmaceutical machinery.

Please leave your suggestions below and provide an effective contact information to receive our feedback. Thank you!

Service Hotline

+86-13825463522© Copyright 2024 Huizhou Pingfang pharmaceutical machinery Co.,Ltd. All rights reserved.