PRODUCTS

PRODUCTS

PRODUCTS

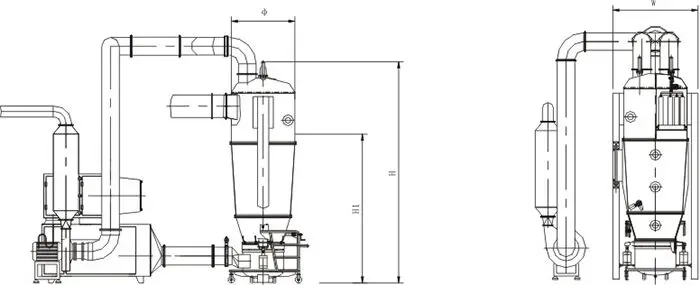

Fluid Fluidized Bed Drying and Granulator Machine for Solid Beverage Drinking Powder, Medicine Powder

Product description

Technical Parameter

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Description

The machine is a process machine widely applied for solid preparation production in the pharmaceutical industry. It has such functions as mixing, granulating, drying, etc. It is also widely used in such industries as medicine, chemical industry, food,etc.

Features

The machine is a new machine researched and developed successfully by our company according to China’s actual conditions after absorbing and digesting internationally advanced technology. It has such features as reasonable structure, stable performance, convenient operation, no dead corners, and no exposed bolts. The machine adopts PLC automatic control. All operations are completed automatically according to the process parameters set by users. All process parameters can be printed and the original records are true and reliable. It fully meets the requirements for medicine production in GMP.

Working principle:

The machine is composed of the main machine, air handling system, heating system, slurry handling system, control system, etc. When it works, the materials enter the silo of the boiling granulator. Set the procedures and parameters according to process requirements and the machine will start working. After filtered by the air handling system and heated by the heating system, the air enters the main machine. The slurries are sent by the slurry handling system into the spray gun and sprayed onto the materials in the cavity to carry out agglomeration of powders and form granules. After the operations are completed according to the set procedures and parameters, the material silo is pushed out and assembled onto the conical hopper of the lifting material transferring machine for lifting discharging, or is pumped to a high position by the vacuum feeder for granule sizing by the granule sizing machine, so as to effectively control dust pollution and cross contamination.

Detailed Images

Next

None