Product Categories

Product Details

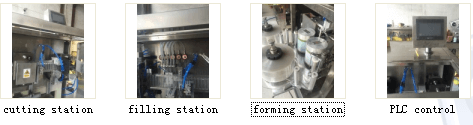

GGS-118 (p2) Plastic Ampoule Filling Machine

Focus on professional manufacturer and supplier for pharmaceutical machinery, pharmaceutical packing material company, who is standing firmly with a good reputation in the industry of China pharmaceutical machinery.

Category:

Product Details

Working station:

Application:

Factory Newest price GGS-118 P2 Automatic plastic ampoule oral liquid filling and sealing machine with GMP and ISO is suitable for oral Liquid , pesticide and pulp category, etc. for Medical , Food, Cosmetic.

Main application:

1). Controlled by PLC, the frequency conversion can be change in finely variable speeds.

2). All 6 processed form spreading roll, plastic ampoule bottle fomring, filling, sealing and the end, printing serial numbers, cutting, and end, cutting apart, controlled by programming.

3). The filling head doesn't drop, leak, rise in bubbled and spill over.

4). All are made of high-quality stainless steel, according with the standard GMP.

5). Mostly pneumatic components and wirings adopt inward fitting.

6). Automatic and mechanical bottling, precise calculation and limited deflection.

Features:

1) PLC control, frequency conversion regulates the speed steeplessly.

2) Finish the whole process automatically, including 7 steps in total as putting packing material, forming, filling, printing lots number, punching, creasing and cutting apart.

3) Hum-machine interface, operate easily and clearly.

4) No leaking, bubbles or overflowing in filling process.

5) All are made of high-quality stainless steel, accord with the ISO and GMP

6) Main pneumatic components and eclectic appliances are imported

7) Tow kinds of filling system: automatic filling or electric peristaltic pump and mechanical filing, precise calculation with slight error.

Technique parameters:

|

Max. forming depth |

12mm |

|

Cutting frequency |

0-20times/min |

|

Packing material |

PVC/PE (0.2-0.4)X120mm |

|

Filling dosage |

1-50ml |

|

Installed power |

4.5kw |

|

Voltage |

220v, 50Hz, 1phase |

|

Weight |

750kg |

|

Outer size |

2260x850x1500mm |

Inquiry

Related Products

undefined

Dear users, thank you for your attention and support to Pingfang pharmaceutical machinery.

Please leave your suggestions below and provide an effective contact information to receive our feedback. Thank you!

Service Hotline

+86-13825463522© Copyright 2024 Huizhou Pingfang pharmaceutical machinery Co.,Ltd. All rights reserved.